Skip to content

Skip to content Custom-built for precision, durability, and maximum throughput in demanding applications.

Pharma-Grade Precision. Designed for Repeatable Perfection.

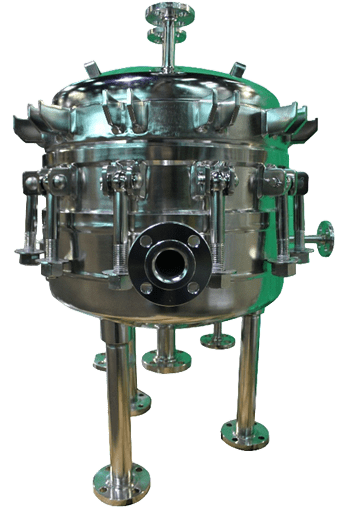

Closed-vessel filtration under pressure or vacuum—ideal for solid collection in sanitary or hazardous environments. Trusted by top pharmaceutical, API, and specialty chemical manufacturers.

Versatile. Proven. Built to Last.

Our flagship filter for chemical and food processing, with over 20,000 units in service. Delivers consistent clarity and cost-efficiency with every batch.

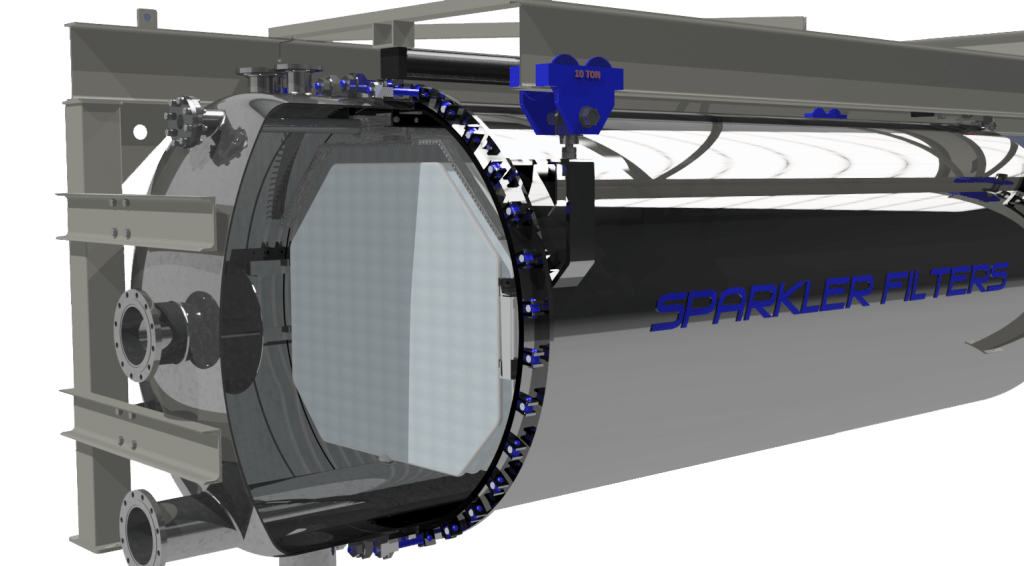

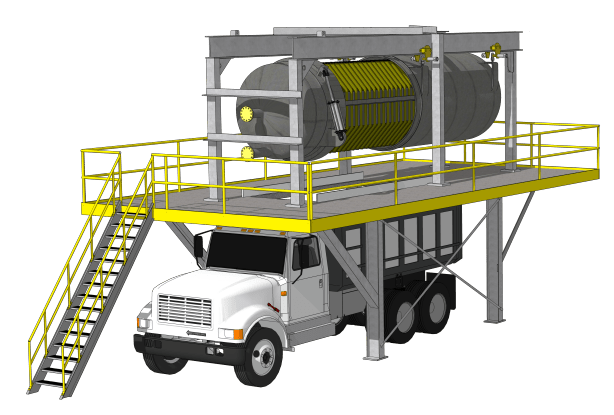

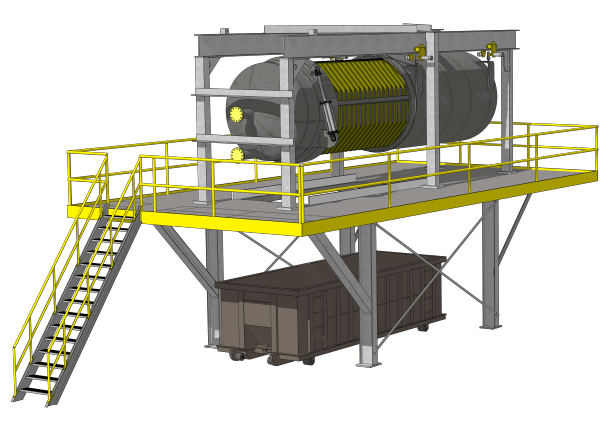

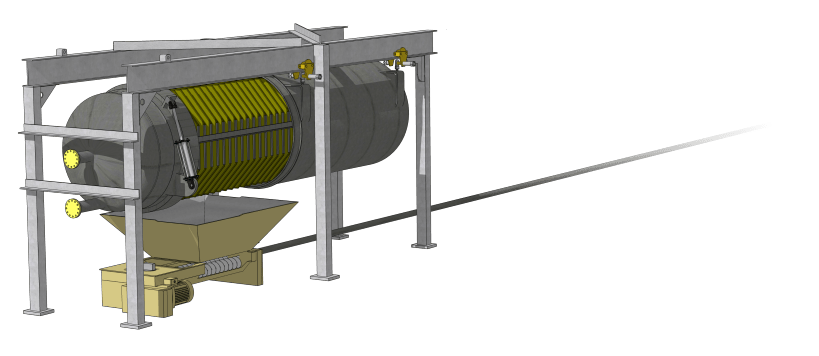

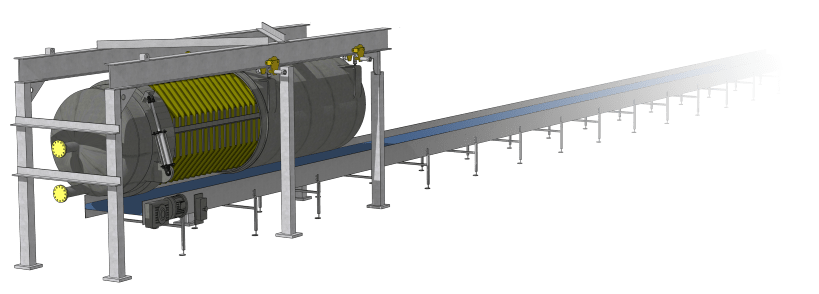

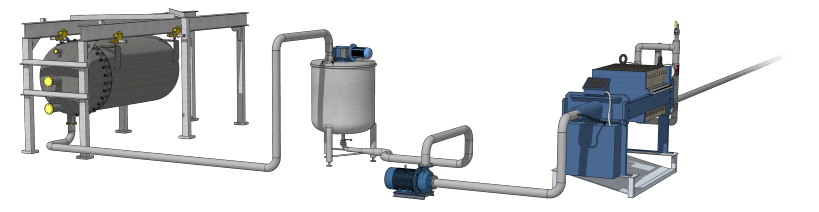

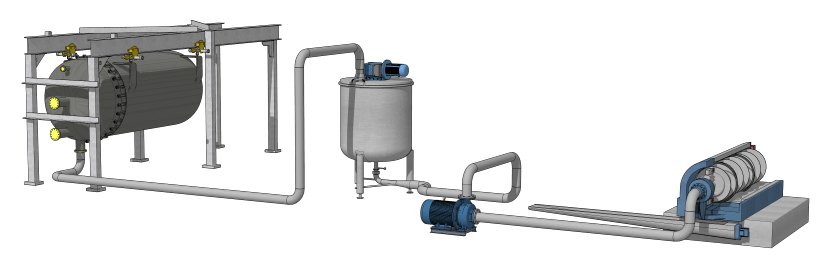

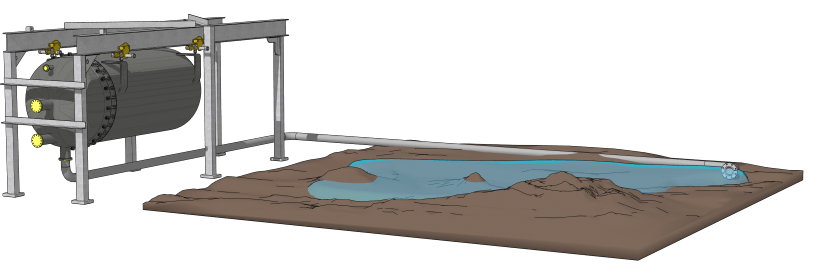

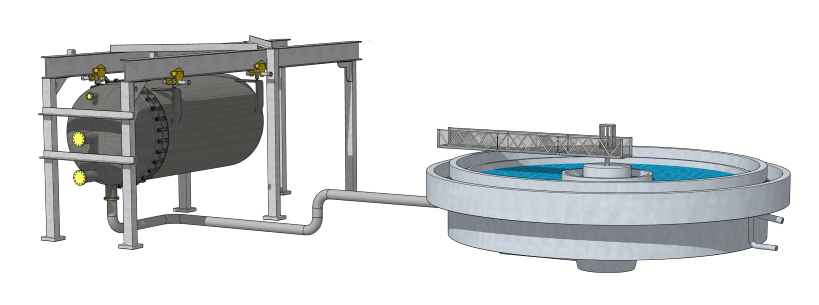

Self-Cleaning. High Volume. Built for Scale.

Automated, heavy-duty filtration for mining, chemical, and ultrafine separation applications. Available in wet or dry cake discharge models. One unit has run continuously in molten sulfur production since 1979.

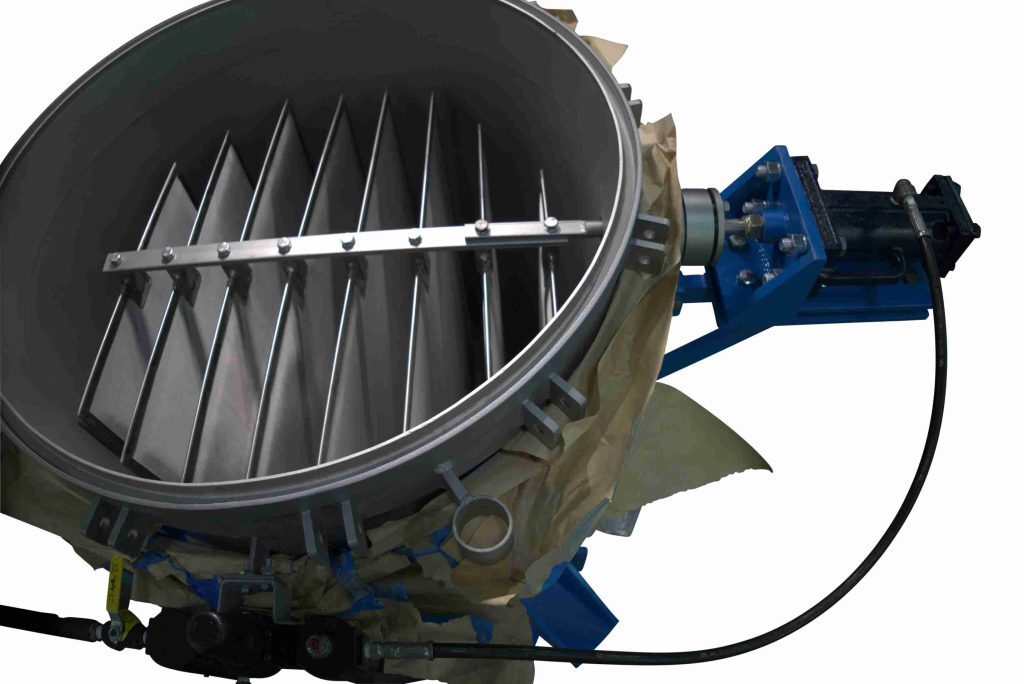

Self-Cleaning. Precision Performance.

Small footprint: Vertical tank with vertical filter plate. Self-cleaning and available in wet cake or dry cake discharge configurations. Available in sizes from 40ft² – 660ft².

Zero Heel. Generational Reliability.

Clean operating design with zero heel. Ideal in pharmaceutical, chemical and food and beverage applications.

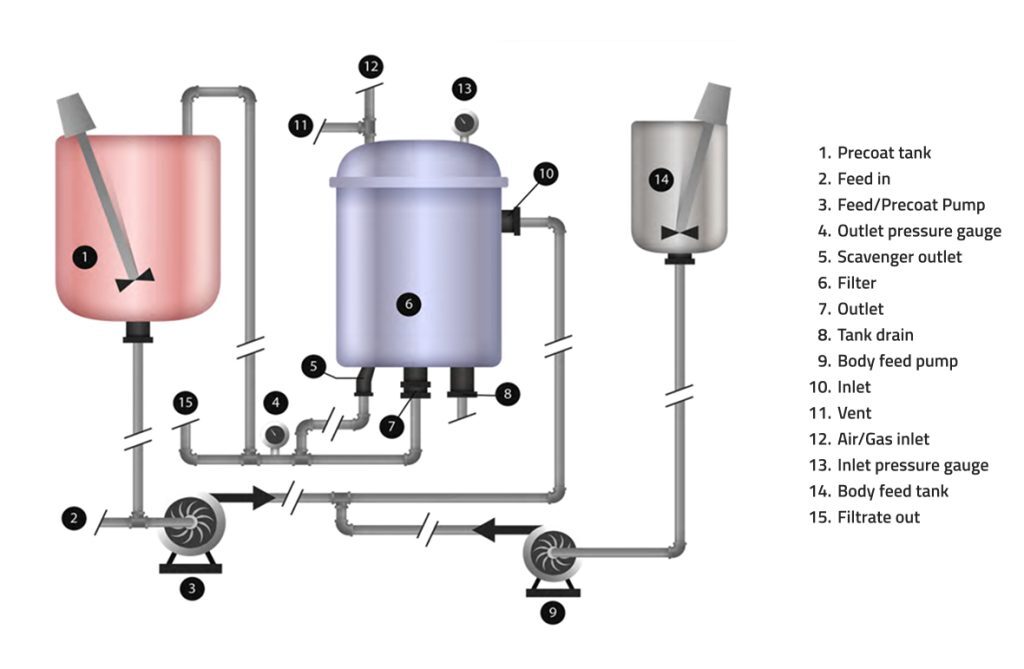

The World’s Most Reliable Polishing Filter.

Designed for use as a polishing filter in semi-continuous operations. Double the filter area per plate greatly reduces footprint.

“Going with Sparkler is like buying insurance against failure.”

50,165+ successful installations across 80+ countries.

Wherever You Operate, Sparkler Delivers.

Manufactured in the USA since 1928.

Built to outlast and outperform in the toughest conditions.

From quote to startup—and every batch after.

Our engineers partner end-to-end, elevating teams with hands-on support and training.

“Used by 7 of the world’s 10 largest chemical companies and leading pharma manufacturers across the globe

Whether you're running a GMP-certified pharma line or pulling lithium from brine, Sparkler® has the filter—and the track record—to make it shine.

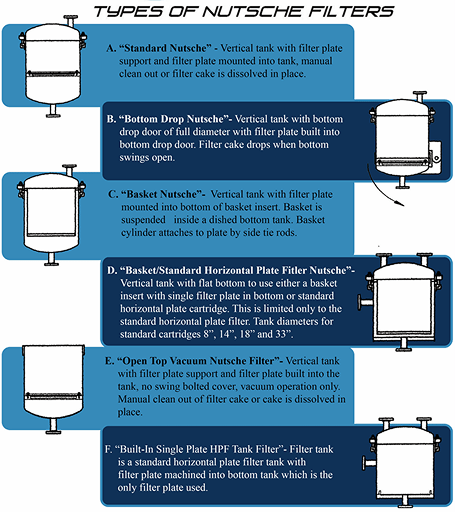

Start here if you’re figuring out what filter fits your process.

For engineers, process nerds, and anyone who wants to filter smarter.

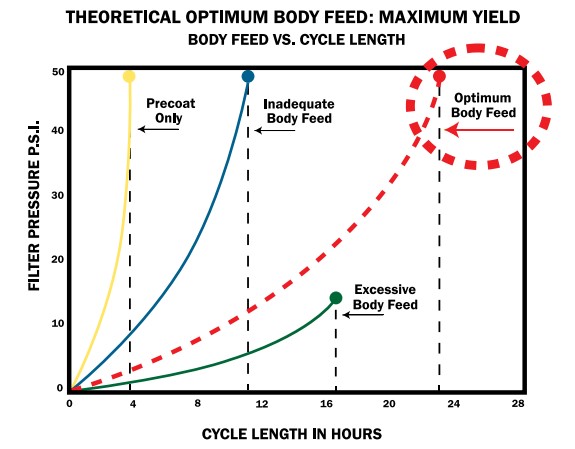

Solid/liquid separation theory

Real-world guidance to improve clarity, uptime, and throughput.

The Filter Inside the Filter.

Automated page speed optimizations for fast site performance