Skip to content

Skip to content Home > Process Tips

The classic fable of the Tortoise and the Hare can be applied to industrial filtration principles, particularly when understanding precoat filtration. , differential pressure, and flow rate optimization.

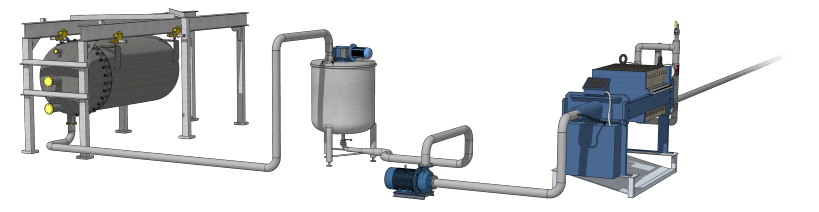

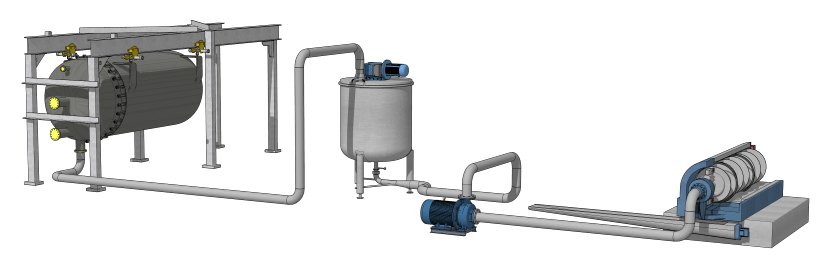

Imagine a one-mile race on a four-lap track. Before the race begins, the track must be properly conditioned—this is equivalent to precoat formation in a filtration system.

Application :

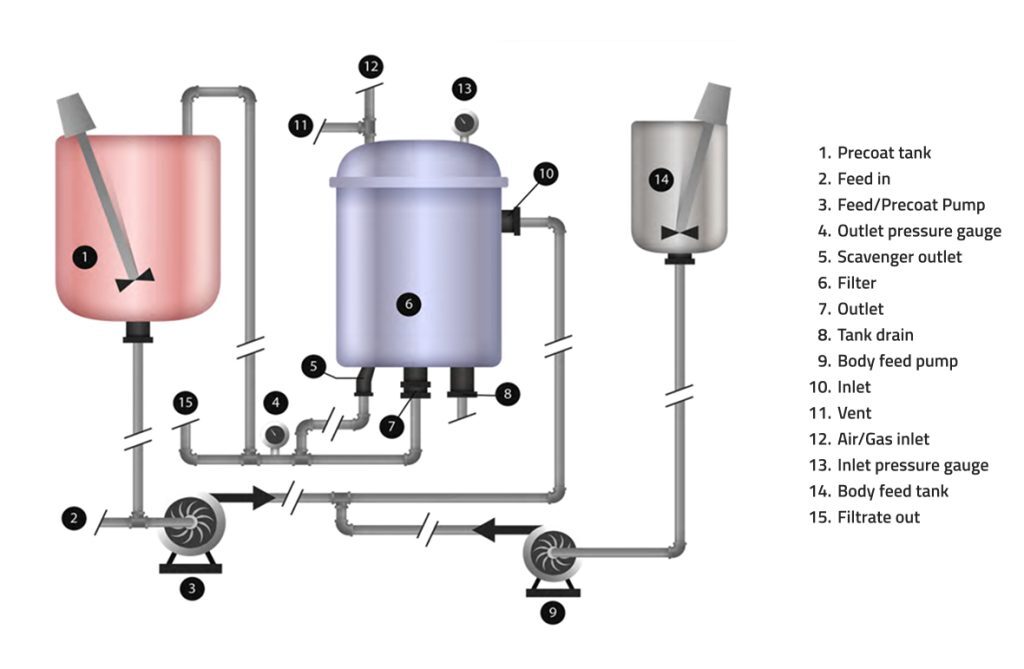

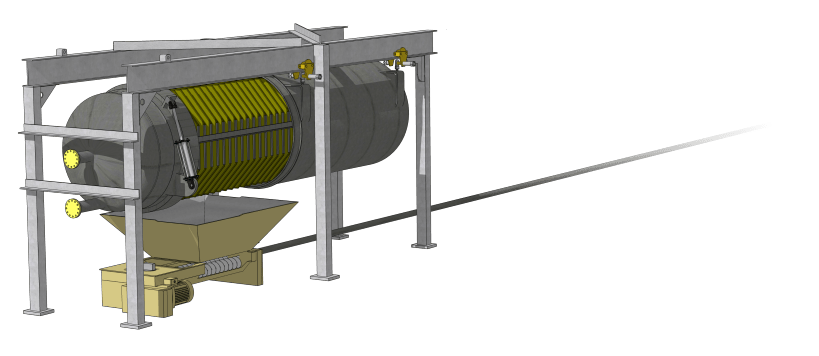

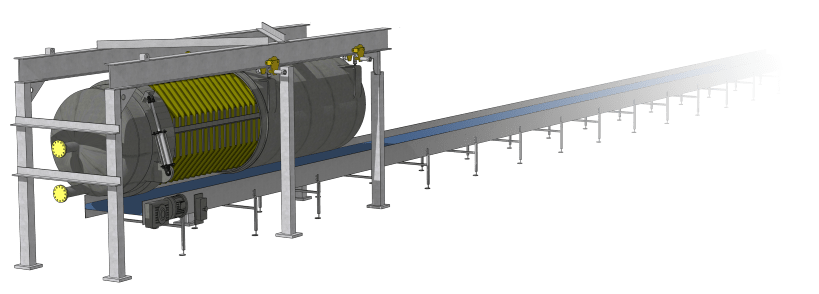

A properly formed precoat will take the ~50% open area from wire mesh or other media and convert it to a porous depth filter of >90% functional filter area. A well-formed precoat should have a consistent differential pressure (dP) and match historical data. If the precoat pressure drop does not match expectations, it signals uneven deposition, improper dosing of filter aid, or premature compaction.

Just as a race strategist maps out pace goals, filtration engineers must graph differential pressure vs. flow rate to find the optimal operating curve.

Application :

Graphing historical dP vs. cycle time allows operators to predict when the system will reach its optimal endpoint, preventing excessive compaction and ensuring consistent throughput across cycles. Click here to download a simple example batch log.

When the race begins, the Tortoise represents the main filtration phase, where steady, controlled flow leads to optimal performance.

Application :

Operators must balance flow rate vs. pressure drop to maintain optimal filtration efficiency. Excessive driving force (ΔP beyond 15 PSI) significantly reduces effective filter area, increasing resistance and reducing cycle time

The key to process stability is the ability to measure and track precoat performance over time.

If there are variations in these values, engineers must investigate:

Application :

Consistent cycle-to-cycle monitoring helps detect small efficiency losses before they escalate into process failures.

Monitoring differential pressure (DP) is one of the easiest ways to understand what's happening inside your filter system.

For reusable media :

If DP drops suddenly between cycles without a bag change (e.g., 10 to 5), you may have:

If the next cycle starts at 1 psid, something's wrong :

The Tortoise and the Hare fable provides a useful analogy for understanding filtration performance:

Differential Pressure Tracking helps optimize cycle longevity and functional filter area utilization.

Cycle-to-cycle consistency ensures long-term filtration reliability by minimizing unexpected efficiency losses.

Automated page speed optimizations for fast site performance