Skip to content

Skip to content Home > Horizontal Plate Filters > V/VR polishing filter

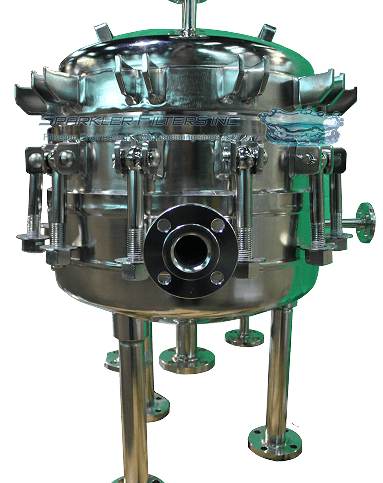

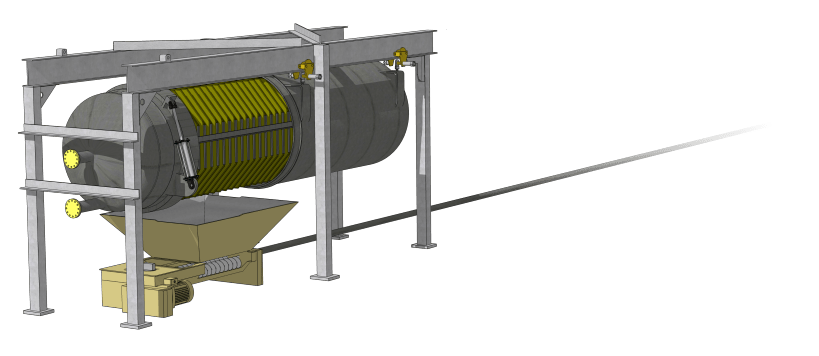

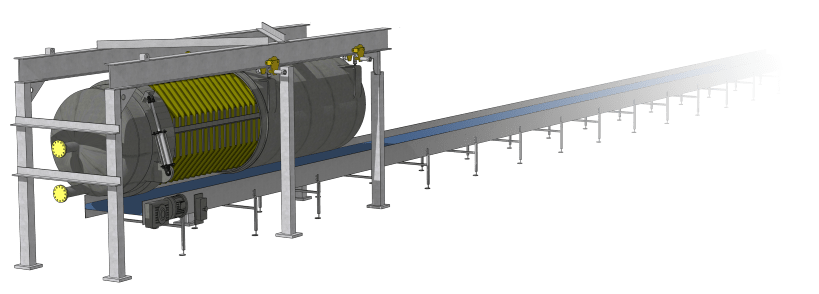

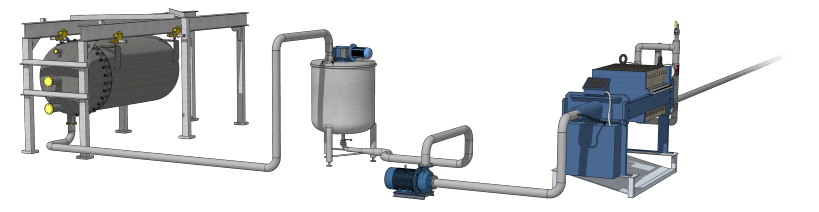

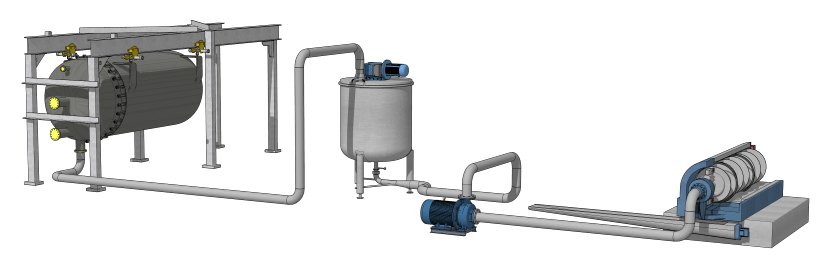

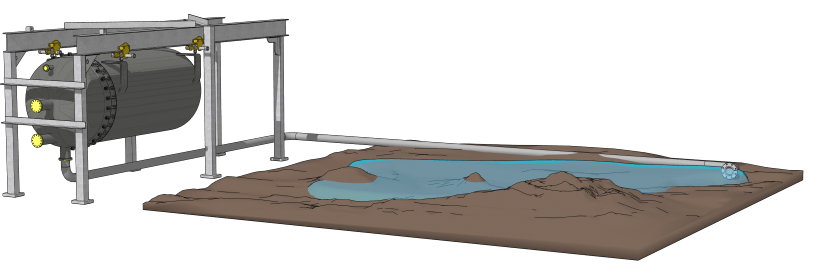

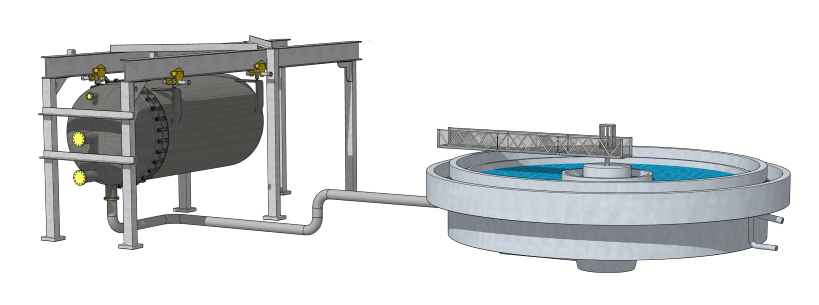

The Sparkler® V and VR Horizontal Plate Filters are versatile, high-performance filtration solutions that excel in semi-continuous or continuous low-solid polishing applications. These models combine innovative features with a compact design to ensure efficiency, reliability, and ease of operation. While they share many core functionalities, the V and VR filters are tailored to meet distinct industry needs.

Both models deliver superb surface area while maintaining a minimal operational footprint, making them ideal for a variety of manufacturing environments.

Filters from both the top and bottom sides of each plate, effectively doubling the filter area within the same physical space compared to standard horizontal plate filters.

Constructed from materials such as 304 S.S., 316 S.S., Hastelloy, and Carbon Steel, ensuring durability and adaptability to diverse chemical environments.

Supports a wide range of filter media, including filter paper, synthetic materials, wire mesh, and membrane media. Click here for more information on Filter Media.

Provides robust performance at a competitive price point. The V model's reusable media and the VR model's disposable options ensure lowest operational costs in industrial filtration. 1/10th cost of competitive technologies.

Enhances cleanability, ensures zero-heel filtration, eliminates venting requirements, and improves product recovery. Ideal for industries requiring stringent sanitary conditions or high-value products.

The Sparkler® V and VR Horizontal Plate Filters have established themselves as trusted solutions in industries worldwide, excelling in polishing applications where efficiency and reliability are critical.

Curious if we’ve handled your specific application? With decades of expertise, the answer is almost always “yes.” Contact us today to discuss how the Sparkler® V and VR Filters can meet your needs.

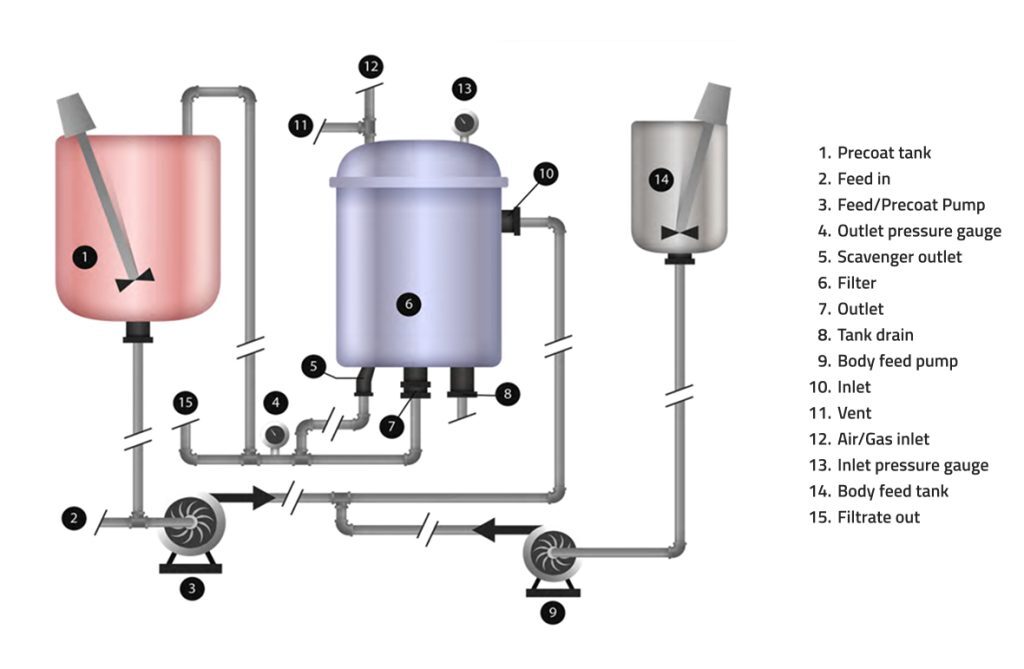

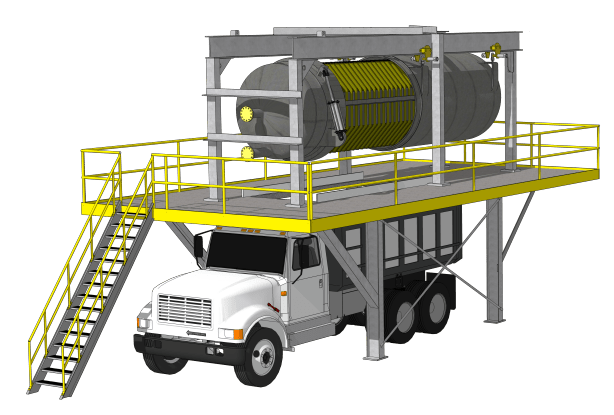

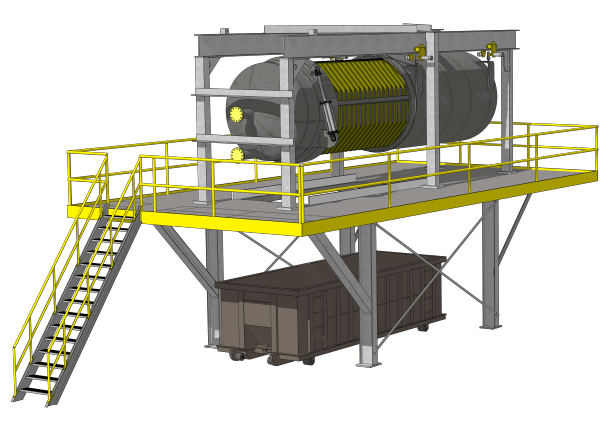

Click here for detailed guidance and expert tips on planning single-filter projects — including auxiliary equipment, system configuration, and cost-saving insights. For multi-filter or continuous operation setups, click here to explore additional solutions.

Unmatched Efficiency:

Zero heel, complete recovery of product for maximum efficiency.

Tailored Solutions:

Custom-built designs to meet the unique challenges of your application.

Exceptional Support:

A dedicated team of experts ready to assist with your filtration needs.

With nearly a century of expertise in liquid filtration, Sparkler® Filters provides tailored solutions to meet unique process challenges. Our commitment to innovation, quality, and customer satisfaction ensures that you receive a filtration system optimized for performance and reliability.

For assistance in selecting the appropriate filter type or to discuss customization options for your application, please fill out our Application Data Sheet or Contact us directly at (936) 756-4471. Our team of experts is ready to provide the support and solutions you need.

Automated page speed optimizations for fast site performance