Skip to content

Skip to content Home > Horizontal Plate Filters > Standard Horizontal Plate Filter

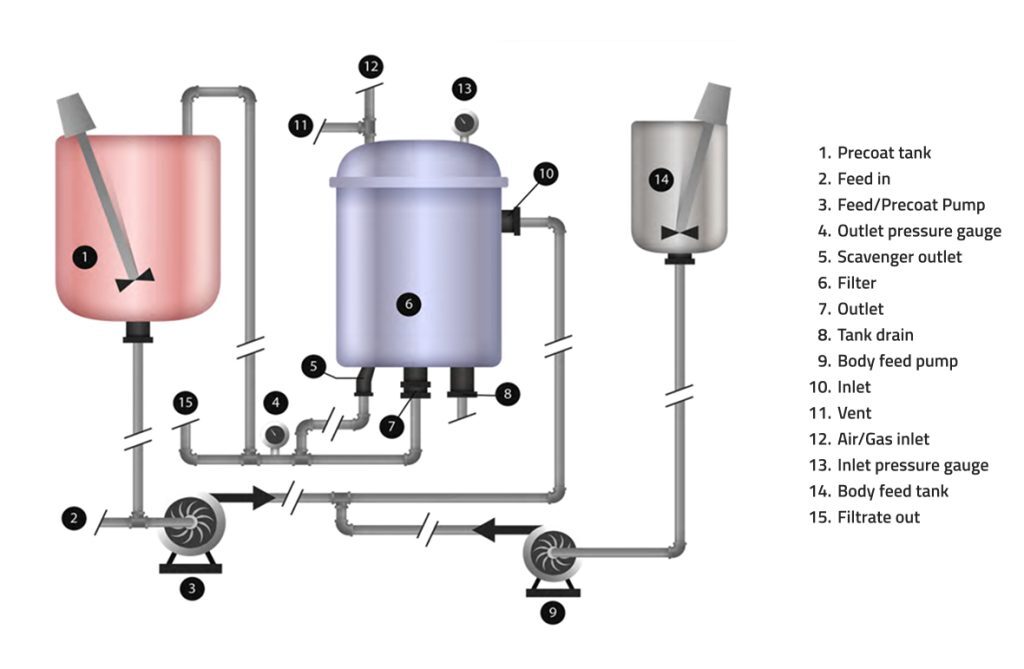

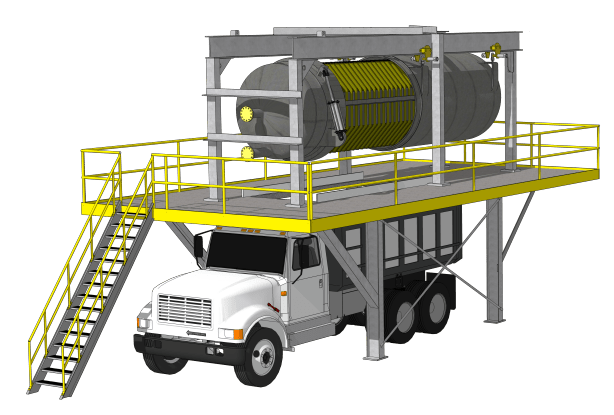

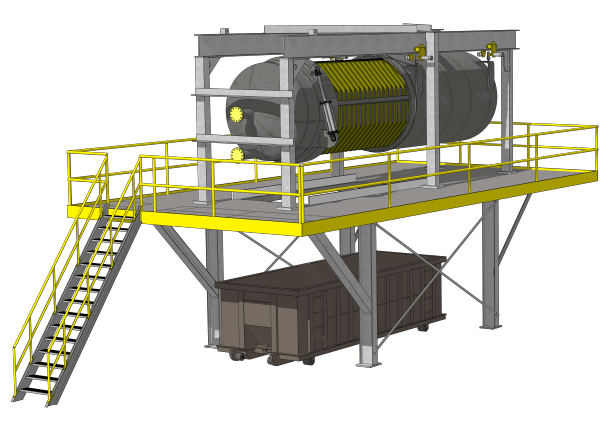

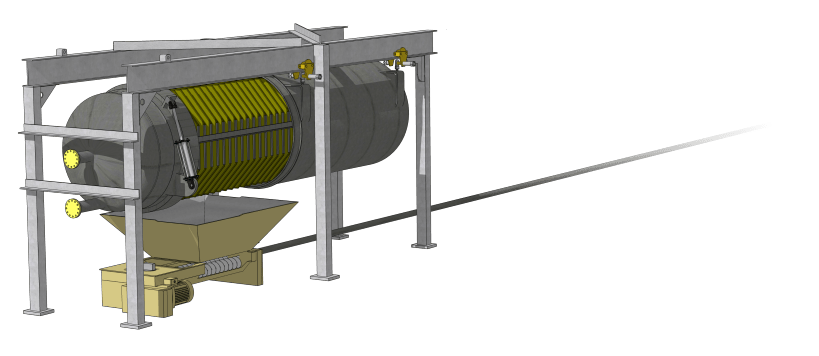

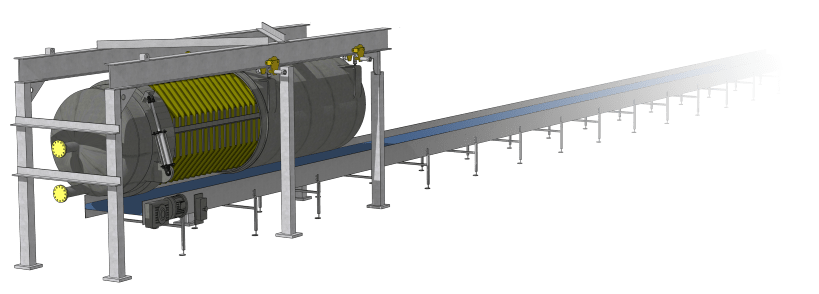

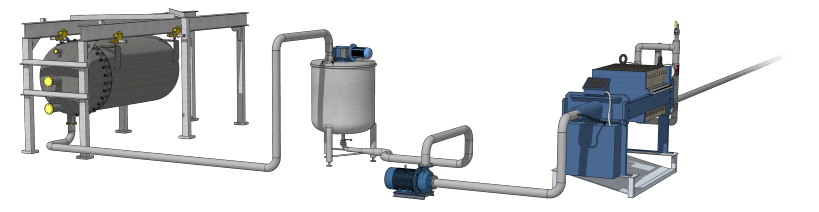

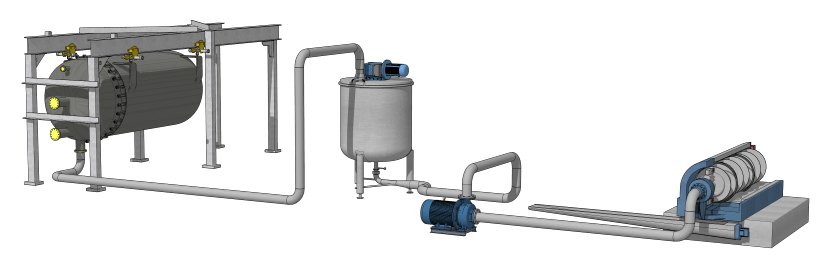

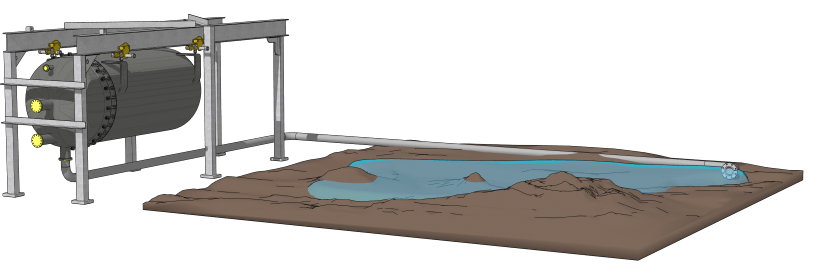

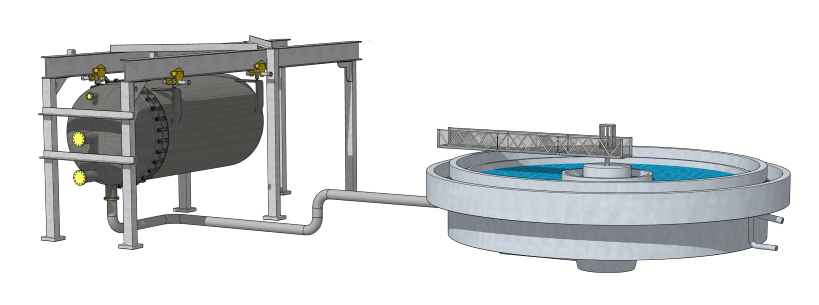

Introducing the Sparkler® Standard Flow Horizontal Plate Filter (HPF)—our flagship filtration solution is internationally renowned for its versatility, efficiency, and cost-effectiveness. Designed to cater to a wide array of industrial applications, the Standard Flow HPF is the preferred choice for processes requiring reliable, repeatable and efficient filtration.

With over 20,000 Sparkler® Horizontal Plate Filters in operation worldwide, our filters have been tested and proven across thousands of unique applications. Standard Flow HPF’s versatility enables it to excel in chemical processing, food and beverage, contract manufacturing/tolling, precious metal recovery and pharmaceutical industries.

This filter is particularly well-suited for processes involving diatomaceous earth (DE) and activated carbon , achieving ultrafine filtration with micron efficiencies below 1 micron. In nearly all liquid/solid applications requiring 0.01–100 micron filtration and ~0.001–20% solids, the Standard Flow HPF delivers unmatched consistency, high-performance separation, and the lowest operating cost of any filtration technology. It’s the proven, dependable choice trusted across industries.

Curious if we’ve handled your specific application? With decades of expertise, the answer is almost always “yes.” Contact us today to discuss how the Standard Flow HPF can alleviate your separation anxiety.

| Diameter Group | Sparkler Model | Filter Area (FT²) | Cake Capacity (FT³) | Weight Cartridge Only (lbs) | Tank Volume, No Cartridge (US Gallons) | Tank Volume, Cartridge Inserted (US Gallons) | |||

|---|---|---|---|---|---|---|---|---|---|

| With Scavenger | Outlet Only | With Scavenger | Outlet Only | With Scavenger | Outlet Only | ||||

| 8" Diameter | 8-3 | 1 | 0.073 | 16.75 | |||||

| 8" Diameter | 8-6 | 2 | 0.146 | 24 | 3.75 | 3.375 | |||

| 14" Diameter | 14-S-4 | 3.56 | 0.131 | 53 | 41 | 10.5 | 13 | 9.5 | 12.375 |

| 14" Diameter | 14-S-7 | 6.23 | 0.229 | 72 | 60 | 10.5 | 13 | 9.375 | 12 |

| 14" Diameter | 14-D-4 | 3.52 | 0.445 | 68 | 55 | 10.5 | 13 | 9.5 | 12.125 |

| 18" Diameter | 18-XS-6 | 9.66 | 0.094 | 108 | 89 | 19.125 | 24.125 | 17.5 | 22.75 |

| 18" Diameter | 18-XS-11 | 17.82 | 0.172 | 157 | 139 | 19.125 | 24.125 | 16.75 | 22 |

| 18" Diameter | 18-XS-17 | 27.54 | 0.266 | 217 | 199 | 30 | 35 | 26.75 | 32 |

| 18" Diameter | 18-XS-24 | 38.88 | 0.375 | 287 | 269 | 30 | 35 | 25.75 | 31 |

| 18" Diameter | 18-XS-36 | 58.32 | 0.91 | 407 | 389 | 41 | 46 | 34.75 | 40 |

| 18" Diameter | 18-S-4 | 6.48 | 0.237 | 93 | 75 | 19.125 | 24.125 | 17.75 | 23 |

| Sparkler Model | Filter Area (Sq. Ft.) | Cake Capacity (Cu. Ft.) |

|---|---|---|

| 8-3 | 1 | 0.073 |

| 8-6 | 2 | 0.146 |

| 14-S-4 | 3.56 | 0.131 |

| 14-S-7 | 6.23 | 0.229 |

| 14-D-4 | 3.52 | 0.445 |

| 18-XS-6 | 9.66 | 0.094 |

| 18-XS-11 | 17.82 | 0.172 |

| 18-XS-17 | 27.54 | 0.266 |

| 18-XS-24 | 38.88 | 0.375 |

| 18-XS-36 | 58.32 | 0.91 |

| 18-S-4 | 6.48 | 0.237 |

| 18-S-7 | 11.34 | 0.414 |

| 18-S-11 | 17.82 | 0.651 |

| 18-S-15 | 24.3 | 0.887 |

| 18-S-23 | 37.26 | 1.36 |

| 18-S-30 | 48.6 | 1.774 |

| 18-D-4 | 6.44 | 0.776 |

| 18-D-6 | 9.66 | 1.164 |

| 18-D-8 | 12.88 | 1.552 |

| 18-D-12 | 19.32 | 2.328 |

| 18-D-16 | 25.76 | 3.104 |

| 18-XD-4 | 6.48 | 1.849 |

| 18-XD-6 | 9.66 | 2.768 |

| 18-XD-8 | 12.88 | 3.69 |

| 33-XS-10 | 56.3 | 1.173 |

| 33-XS-13 | 73.19 | 1.525 |

| 33-XS-16 | 90.08 | 1.877 |

| 33-XS-21 | 118.23 | 2.463 |

| 33-XS-29 | 163.27 | 3.401 |

| 33-XS-42 | 236.46 | 4.926 |

| 33-S-7 | 39.41 | 2.46 |

| 33-S-9 | 50.57 | 3.17 |

| 33-S-11 | 61.93 | 3.87 |

| 33-S-14 | 78.82 | 4.93 |

| 33-S-19 | 107 | 6.68 |

| 33-S-28 | 157.64 | 9.85 |

| 33-D-7 | 39.27 | 5.84 |

| 33-D-9 | 50.49 | 7.5 |

| 33-D-12 | 67.32 | 10 |

| 33-D-17 | 95.37 | 14.17 |

| Sparkler Model | Filter Area (m²) | Cake Capacity (m³) |

|---|---|---|

| 8-3 | 0.093 | 0.0021 |

| 8-6 | 0.186 | 0.0041 |

| 14-S-4 | 0.331 | 0.0037 |

| 14-S-7 | 0.579 | 0.0065 |

| 14-D-4 | 0.327 | 0.0126 |

| 18-XS-6 | 0.897 | 0.0027 |

| 18-XS-11 | 1.656 | 0.0049 |

| 18-XS-17 | 2.558 | 0.0075 |

| 18-XS-24 | 3.612 | 0.0106 |

| 18-XS-36 | 5.418 | 0.0258 |

| 18-S-4 | 0.602 | 0.0067 |

| 18-S-7 | 1.054 | 0.0117 |

| 18-S-11 | 1.656 | 0.0184 |

| 18-S-15 | 2.258 | 0.0251 |

| 18-S-23 | 3.462 | 0.0385 |

| 18-S-30 | 4.515 | 0.0502 |

| 18-D-4 | 0.598 | 0.022 |

| 18-D-6 | 0.897 | 0.033 |

| 18-D-8 | 1.197 | 0.0439 |

| 18-D-12 | 1.795 | 0.0659 |

| 18-D-16 | 2.393 | 0.0879 |

| 18-XD-4 | 0.602 | 0.0524 |

| 18-XD-6 | 0.897 | 0.0784 |

| 18-XD-8 | 1.197 | 0.1045 |

| 33-XS-10 | 5.23 | 0.0332 |

| 33-XS-13 | 6.8 | 0.0432 |

| 33-XS-16 | 8.369 | 0.0532 |

| 33-XS-21 | 10.984 | 0.0697 |

| 33-XS-29 | 15.168 | 0.0963 |

| 33-XS-42 | 21.968 | 0.1395 |

| 33-S-7 | 3.661 | 0.0697 |

| 33-S-9 | 4.698 | 0.0898 |

| 33-S-11 | 5.753 | 0.1096 |

| 33-S-14 | 7.323 | 0.1396 |

| 33-S-19 | 9.941 | 0.1892 |

| 33-S-28 | 14.645 | 0.2789 |

| 33-D-7 | 3.648 | 0.1654 |

| 33-D-9 | 4.691 | 0.2124 |

| 33-D-12 | 6.254 | 0.2832 |

| 33-D-17 | 8.86 | 0.4012 |

With nearly a century of expertise in manufacturing liquid filtration equipment, Sparkler® Filters is dedicated to delivering tailored solutions to your specific needs. The Legacy Sparkler Filter exemplifies our commitment to reliability, quality, and repeatable performance — making it the trusted choice in industrial filtration processes.

For assistance in selecting the appropriate filter type or to discuss customization options for your application, please fill out our Application Data Sheet or Contact us directly at (936) 756-4471 . Our team of experts are ready to provide the support and solutions you need.

Automated page speed optimizations for fast site performance