Skip to content

Skip to content Home > Discovery

Determining the right filtration system requires a deep understanding of process requirements, application variables, and filtration options. At Sparkler Filters, our Discovery Service helps customers evaluate their filtration needs—whether they are new to solid-liquid separation or looking for an optimized solution.

While all new filter inquiries include a free initial consultation, this service provides a deeper, more technical evaluation to determine the most effective filtration process for your application. In over 90% of the applications we review, we identify significant savings — often resulting in millions of dollars saved or in increased production. Check out our testimonials and case studies for recent real-world examples where just a few thousand dollars in field service costs delivered returns of 1,000x or more.

Our team of filtration specialists will work closely with you to assess key process parameters and provide data-driven recommendations. This includes:

We analyze critical filtration variables to understand your specific needs:

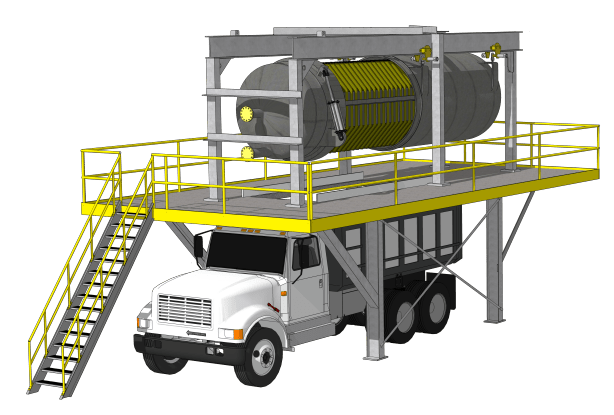

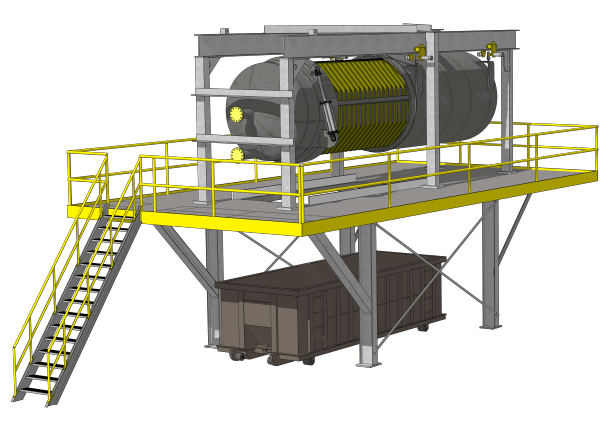

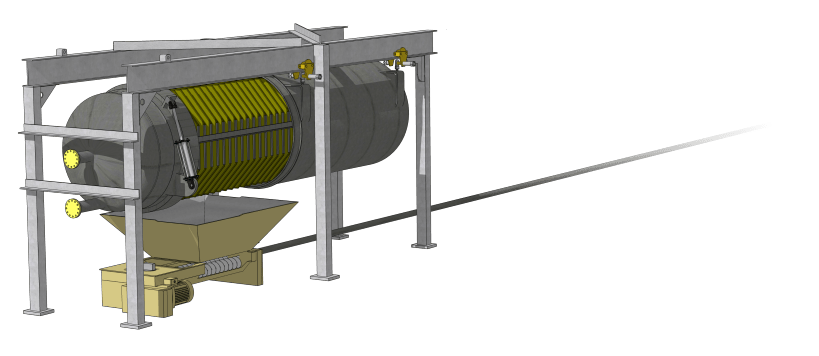

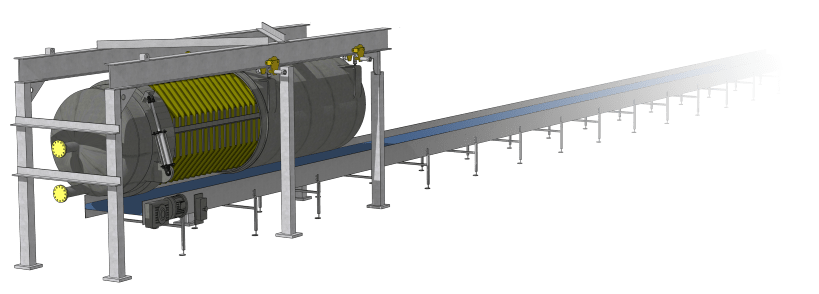

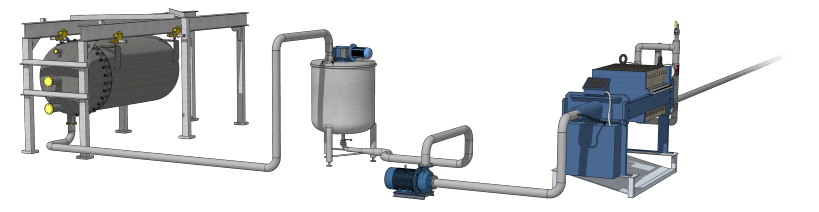

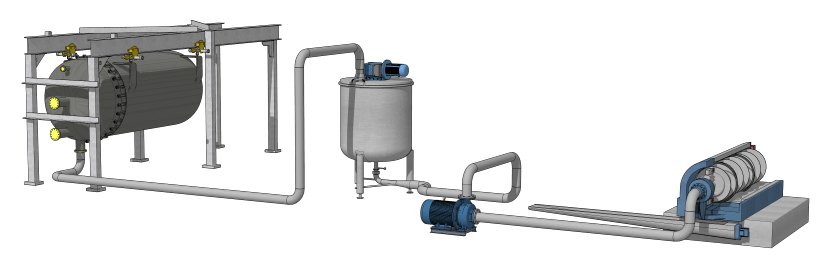

While Sparkler does not conduct lab testing on-site, we assist in setting up testing at customer facilities or third-party labs. Sparkler has Rental Filters available in many different sizes and configurations to assist as needed.

Testing may include :

Using lab or pilot test data, we assist in:

We assist in:

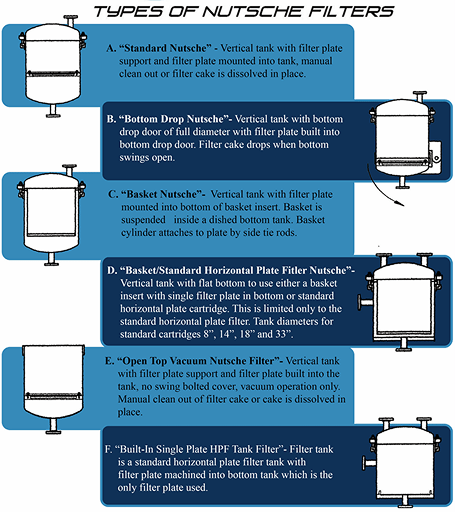

Check these out to help visualize critical variables:

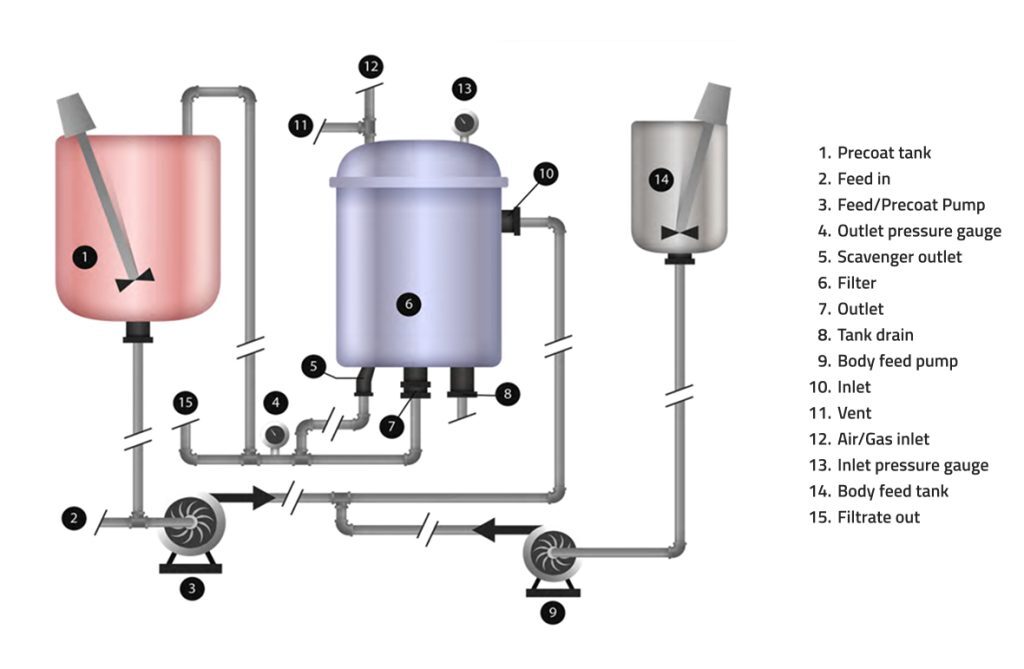

Each filtration application requires specific media to optimize efficiency, compatibility, and cost-effectiveness. Sparkler® Filters offers the following filter media types:

Determining the correct grades of DE or filter aid for precoat, bodyfeed, or slurry mixing

Filter media selection based on process requirements (woven, non-woven, depth, membrane, synthetic, wire mesh)

Evaluating alternative filtration aids such as perlite or rice hull ash to improve throughput and cake formation

If you already have a filtration system in place and need to improve efficiency, reduce costs, or troubleshoot issues, our Process Improvement Services may be a better fit.

Visit the Process Improvement page for :

Automated page speed optimizations for fast site performance